Product Details:

Payment & Shipping Terms:

|

| Model: | EZ-XP-4.0 | Weight: | 100kgs/110KGS |

|---|---|---|---|

| Speed: | 600-750m2/day | Power: | 0.75kw |

| Voltage: | 220V | Electricity Phase: | Single Phase |

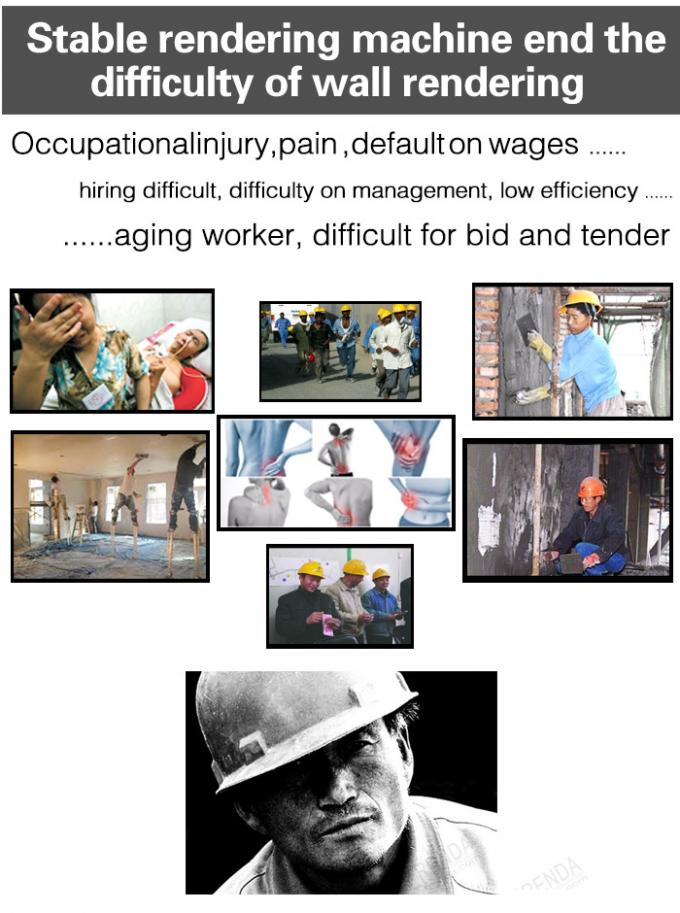

Auto Ez Renda Rendering Machine Cement Render Plastering Clay Wall

Brand Name: EZ RENDA

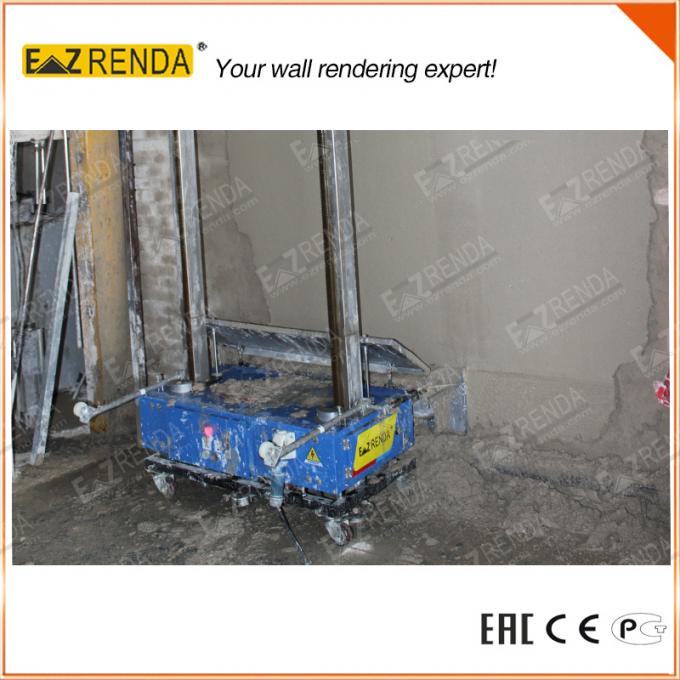

EZ-XP-4.0 is a unique machinery designed for internal wall plastering. and EZ RENDA is the original manufacturer of the rendering machine. See the development of the company, EZ-Renda has 19 patents now.

Its automation instead of traditional manual plastering and professional finishing clear your worries behind.

XP is the newest rendering machine of latest tech.

XP is an ideal rendering machine for big and wide areas, such as store, warehouse etc.

Description:

|

Model NO. |

EZ-XP-4.0 |

|

|

Dimension of L/W/H |

1150*700*500mm/1350*700*500MM |

|

|

Weight |

100kgs/110kgs |

|

|

Electricity Phase |

Single Phase | |

|

Power |

0.75KW/220V/50HZ |

|

|

Control |

Remote Controller (Special Design) |

|

|

Rendering Height Positioning Tool |

Steel Chain (Instead of Old Mobile Ceiling Frame) |

|

|

Vibrator |

3 PCS |

|

|

Rendering Thickness |

4mm-30mm |

|

|

Rendering Speed |

70 - 80 m²/hour |

|

|

Rendering height |

up to 4.2 m ( Standard Equipment Rendering Height 2.85-3.5M ) |

|

|

Length of Plastering trowel |

1000/1200mm |

|

|

Smoothing Knife |

inclusive |

|

|

Material |

Stainless Steel 304 |

|

|

Driving System |

Hydraulic System |

|

|

Finishing |

Coating & Smoothing at the same time |

|

|

HS Code |

8474.31.0000 |

|

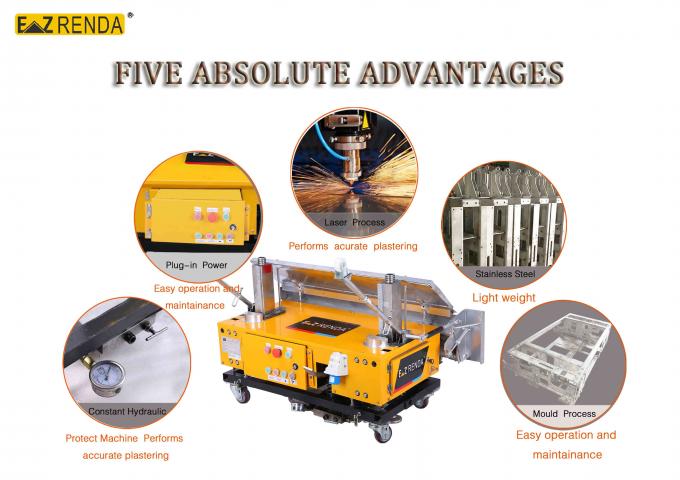

Five absolute advantages:

1, Constant hydraulic--protect machine and ensure the good quality of plastering.

2, Plug-in electric cabinet- Easy operation and maintenance

3, Laser process--high precision contributes to good finishing of plastering

4, Stainless steel --light weight

5, Mold process--Easy operation and maintenance

|

|

EZ RENDA Rendering Machine |

Manual Rendering |

|

Speed/8 hours |

600-750 sqm |

less than 50 sqm |

|

Finishing |

smooth & flat in horizontal & vertical level. Professional mirror finishing. |

always reveal crack, bubbles, etc. |

|

Coating |

Once coating while render up and smooth down |

several times coating by numberless trowels |

|

Procedures |

hydraulic system & traditional spot guide within 10 seconds |

adjust planeness by square bar in circular arc movement again & again |

|

Extra supporting |

electricity |

scaffolding, mop, trowel, square bar, lots of extra tools |

|

Labor Intensity |

two only. Effortless. |

a lot more. Hard work. |

|

Time Consumption |

saving 70% - 80% time |

long time work |

FAQ for the rendering machines:

1- Whether the machine could be used for the external wall and ceiling?

No, it couldn’t at present. We are still working on it. It will coming soon!

2- Whether the hollow and cracking could happen?

Hollows can be avoided because there are three vibrators behind the mortar tank. It creats high pressure to the wall when machine works. And watering before rendering the wall can avoid cracking.

3- How about the finishing effect? Whether it is smooth?

The finishing effect is definitely smooth, no hollow, no cracking. The difference is less than 2mm.

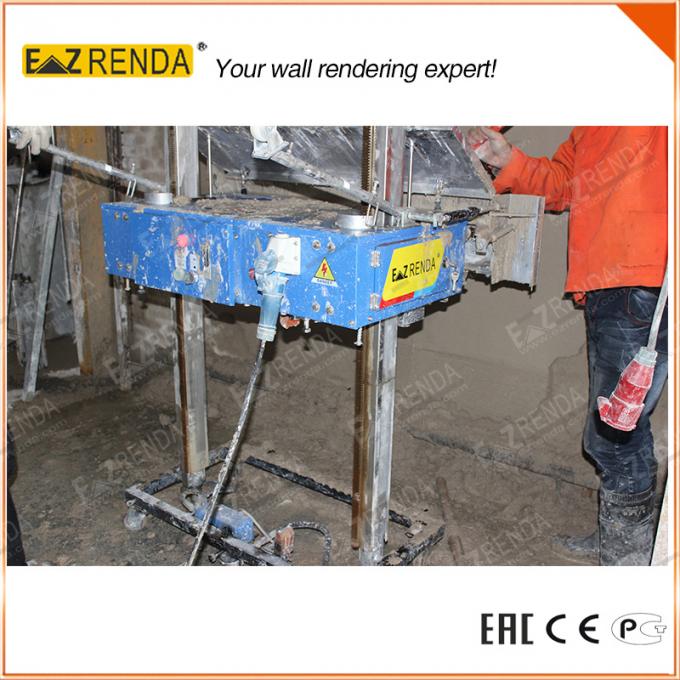

4- How many people need to operate the machine effectively? What is their division of labor?

Normally 3 people are enough to operate the machine, two people operate the machine and one person is in charge of small area repairing.

5- How do we use the machine on walls with openings such as windows and doors? Can it be done with the machine or do we have to do it manually?

All models of machines can definitely render the area which is below and above window.

For the machine VISTA and XP: Supply little mortar at first, when the machine reach the open area, the mortar is nearly used up. After the machine passed the open area, press the “STOP” button and supply the mortar to render the top area then.

6- How is the machine cleaned after use?

After finish using the rendering machine, the cleaning job needed to be done after the power is cut off. Use water to wash the caster, plastering tank, directional pipes, extensions. The machine body and the buttons could only be cleaned by the cloth.

7- What is the life for the m/c?

3-5 years at normal use

8- What maintenance is required at site?